Product List:

- Free Cutting Material Series

- Carbon and Alloy Steel

- Copper and Copper Alloys

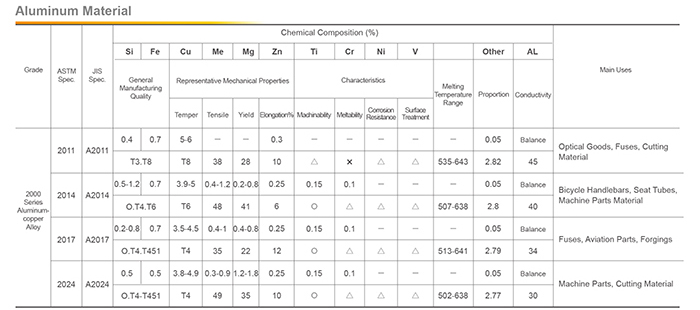

- Aluminum and Aluminum Alloys

- Stainless Steel

- Steel Pipe

- Shaped Metal Bars

| Free Cutting Steels | JIS G4804 | ||||||

| Mark | Similar Specifications (JIS) |

Chemical Composition (%) | Uses | ||||

| C | Mn | P | S | Pb | |||

| 12L14 | SUM24L | 0.15 max | 0.85~1.15 | 0.04~0.09 | 0.26~0.35 | 0.10~0.35 | Cutting Materials, General Accessory |

| 1215 | SUM23 | 0.09 max | 0.75~1.05 | 0.04~0.09 | 0.26~0.35 |

- | |

| 1215MS | - | 0.09 max | 1.10~1.60 |

0.04~0.09 | 0.33~0.42 | - | |

| 1141 | SUM42 | 0.37~0.45 | 1.35~1.65 | 0.04 max | 0.08~0.13 | High-speed Cutting Materials, Axial | |

| 1144 | SUM43 | 0.40~0.48 | 1.35~1.65 | 0.04 max | 0.24~0.33 | - | |

| Low-Alloyed Steels For Machine Structure Use | JIS G4053 | ||||||||

| Mark | Chemical Composition (%) | Uses | |||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | ||

| SCM415 | 0.13~0.18 | 0.15~0.35 | 0.60~0.90 | 0.03 max |

0.03 max | 0.25 max | 0.90~1.20 | 0.15~0.25 | For shafts, Pistons, Vehicle Parts with Carburizing Hardening Surfaces |

| SCM420 | 0.18~0.23 | 0.15~0.35 | 0.60~0.90 | 0.03 max | 0.03 max | 0.25 max | 0.90~1.20 | 0.15~0.25 | |

| SCM435 | 0.33~0.38 | 0.15~0.35 | 0.60~0.90 | 0.03 max | 0.03 max | 0.25 max | 0.90~1.20 | 0.15~0.30 | Screws, Bolts and Mechanical Parts |

| SCM440 | 0.38~0.43 | 0.15~0.35 | 0.60~0.90 | 0.03 max | 0.03 max | 0.25 max | 0.90~1.20 | 0.15~0.30 | Shaft, Vehicle Parts |

To improve the machinability of carbon steel for machine structure use and low-alloy steel for machine structure use, steel production plants have added extra lead, sulfur, etc. Those with added lead are tagged with ~L1, ~L2 at the end of their material number. Those with added sulfur are tagged with ~S0, ~S1, ~S2 at the end of their material number. After addition, the ingredients have been slightly changed, see table below for details:

| Grade Mark | Chemical Composition (%) | ||||||

| Mn | P | S | Pb | ||||

| Less than the original Mn content's lower limit of 0.40% | Higher than the original Mn content's lower limit of 0.40% |

||||||

| Lower Limit | Upper Limit | Lower Limit | Upper Limit | ||||

| ~L1 | - | - | - | - | - | - | 0.04~0.09 |

| ~L2 | - | - | - | - | - | - | 0.10~0.30 |

| ~S0 | - | - | - | - | - | 0.015~0.035 | - |

| ~S1 | +0.20 | +0.30 | +0.10 | +0.20 | - | 0.04~0.07 | - |

| ~S2 | +0.30 | +0.40 | +0.20 | +0.30 | 0.040 or less | 0.08~0.12 | - |

*The Company’s L series products are mainly ~L2, e.g. SCM415L, SCM415S, SCM435L and SCM435S.

| Stainless Steel | |||||||||||

| Grade | Chemical Composition (%) | Remark | |||||||||

| JIS | AISI | C | Si | Mn | P | S | Ni | Cr | Mo | Other | |

| SUS303 | 303 | 0.15 max | 1.00 max | 2.00 max | 0.20 max | 0.15 min | 8.00~10.00 | 17.00~19.00 | 0.60 max | - | |

| SUS303Cu | - | 0.15 max | 1.00 max | 3.00 max | 0.20 max | 0.15 min | 8.00~10.00 | 17.00~19.00 | 0.60 max | Cu: 1.50~3.50 | |

| SUS316F | 316F | 0.08 max | 1.00 max | 2.00 max | 0.045 max | 0.15 min | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | - | |

| SUS416 | 416 | 0.15 max | 1.00 max | 1.25 max | 0.060 max | 0.15 min | 0.60 max | 12.00~14.00 | 0.60 max | - | |

| SUS430F | 430F | 0.12 max | 1.00 max | 1.25 max | 0.060 max | 0.15 min | 0.60 max | 16.00~18.00 | 0.60 max | - | |

| Free Cutting Brass | |||||||||

| Alloy No. | Chemical Composition (%) | Features and uses | |||||||

| Cu | Pb | Fe | Sn | Zn | |||||

| C3601 | 59.0-63.0 | 1.8-3.7 | <0.3 | Fe + Sn<0.5 | REM | Excellent Machinability and C3601, C3602 Good Extensibility too. Uses: Computers, Electronics, Clocks, Pens, Lighting, Rivets, Nuts, Gears, Valves, Camera Parts, Hardware Parts. |

|||

| C3602 | 59.0-63.0 | 1.8-3.7 | <0.5 | Fe + Sn<1.2 | REM | ||||

| C3603 | 57.0-61.0 | 1.8-3.7 | <0.35 | Fe + Sn<0.6 | REM | ||||

| C3604 | 57.0-61.0 | 1.8-3.7 | <0.5 | Fe + Sn<1.2 | REM | ||||

| C3771 | 57.0-61.0 | 1.0-2.5 | Fe + Sn<1.0 | REM | Excellent hot forging. Uses: precision forging, machine parts. Excellent hot forging and good machinability. Uses: Valves, Watches and Machine Parts. |

||||

Click on the image to enlarge the table of contents ![]()